At a grand opening ceremony and tour in Guaymas, Mexico, Chromalloy announced that its new state-of-the-art gas turbine engine machining facility is operational and producing first article test production on aircraft engine components.

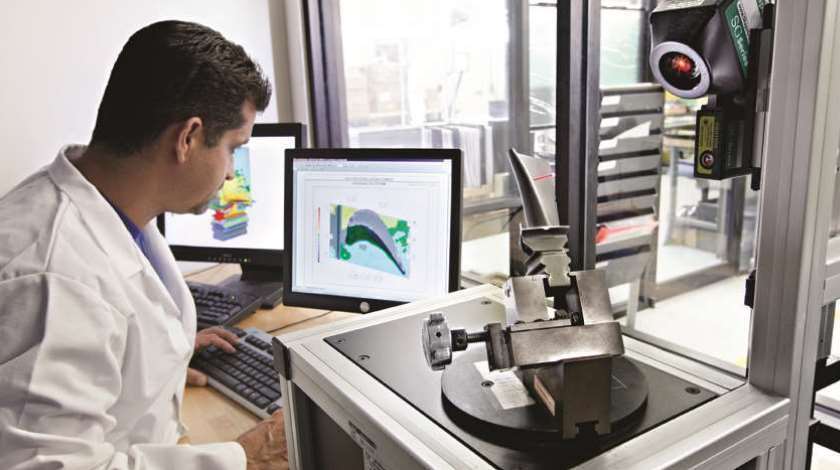

“Chromalloy’s new 36,000 ft² manufacturing center is a dedicated precision machining facility for original equipment manufacturer (OEM) new engine components,” said Thomas Mepham, CEO, Sequa Corporation, during the grand opening ceremony.

“This brand-new plant is a significant part of our growth strategy as a global supplier in the new engine supply chain. We are doubling our previous Guaymas capacity and growing the workforce,” Mepham said, as he and Guaymas state and local officials cut the ceremonial ribbon at the entryway.

The new facility, which utilizes Lean and Operational Excellence principles and workflow designs, has the capacity to machine up to 68,000 gas turbine engine components a year. The facility will be online producing customer orders beginning in January 2016. By year-end 2016, Chromalloy plans to triple its previous Guaymas workforce, to approximately 250 employees. Chromalloy is a subsidiary of Sequa Corporation.

Chromalloy operates a network of gas turbine engine repair and manufacturing centers around the world that provides a broad range of services on components in the engine gas path or hot section.

The company is a leading supplier of technologically advanced repairs, coatings, investment castings, and services for turbine airfoils and other critical engine components. The company provides turbine engine manufacturers and operators in commercial aerospace, defense and energy, with complete manufacturing support and material and supply chain management. Chromalloy facilities include operations, annexes and sales offices in 11 countries.

Source: chromalloy.com