Photo: i1os.com

Reading Time: 2 minutesGE Aviation’s Electronic Engine and Propeller Control (EEPC) system for its H Series turboprop engine has received type certification from the European Aviation Safety Agency (EASA). GE’s EEPC is the business and general aviation industry’s first turboprop offering to combine engine and propeller operations into a single system.

Prior to EASA certification on November 25, EEPC system validation testing totaled more than 200 hours of ground and flight testing. U.S. Federal Aviation Administration (FAA) type certification is expected before the end of this year.

The first application for the EEPC is Nextant Aerospace’s G90XT, a remanufactured and reimagined King Air C90. On October 25, GE Aviation and Nextant successfully completed first flight of the H75-powered G90XT in full EEPC configuration. Nextant expects to achieve U.S. Federal Aviation Administration (FAA) certification and deliver its first EEPC-equipped aircraft in the first half of 2017.

In May, Thrush Aircraft, Inc., and GE Aviation announced plans to develop EEPC-equipped versions of the Thrush 510G. Initially, the EEPC will be introduced on the H80-powered 510G, with planned certification in 2017. In 2018, GE & Thrush plan to offer an EEPC-equipped H85 for 510G operators, providing additional horsepower for crop dusting missions. With another two applications to follow, the EEPC-equipped H Series has already been selected for four aircraft applications.

“EEPC is truly a game changer for turboprop aircraft capability: auto start, single-lever power control, torque limit, temperature limit, speed limit, you name it, the EEPC delivers,” said Brad Mottier, GE Aviation’s VP of Business and General Aviation and Integrated Systems business.

“Speaking as a pilot, the EEPC certification is a landmark achievement for GE and a critical ‘first’ for our industry. From a pure cockpit operability standpoint, pilots will now be able to push for takeoff and not worry about temperatures, speeds or torque, which no other turboprop manufacturer can claim. Pilots can comfortably fly the prop knowing he or she is getting maximum performance from the engine.”

The EEPC includes three key features:

- 1.Electronic Engine Control Unit – The EECU acts as the brain of engine control system, responsible for electronic control of the engine and propeller via a single lever. It auto-starts the engine and automatically prevents overtemp, overspeed and overtorque, leading to longer engine life and easier maintenance.

- 2.The Fuel Metering Unit – The FMU meters how much fuel the engine needs. Integrated with the fuel pump, the FMU guarantees the engine always has the proper amount of fuel – nothing more, nothing less.

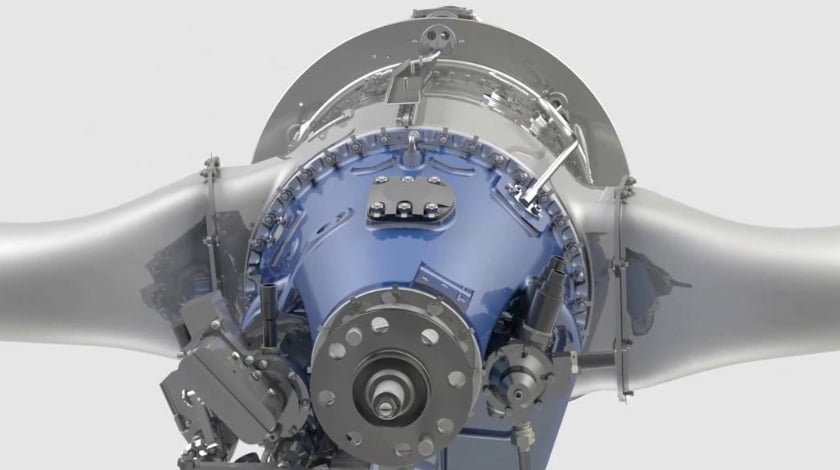

- 3.Electronic Prop Governor – This part controls the propeller speed, forward & reverse blade pitch control. It mechanically prevents the engine and propeller from overtorque and overspeed, again.

The H Series turboprop family incorporates GE’s 3-D aerodynamic design techniques and advanced materials to create a powerful, fuel-efficient, durable engine with no recurrent fuel nozzle inspections and no intermediate hot section inspection required for a multitude of uses: agricultural, business turboprops, commuter and utility aircraft. GE offers H Series turboprop engines with 4000-hour time between overhaul (TBO) for Agriculture, Utility and Business Aviation Aircraft. An extension program is also offered to extend TBOs for in-service engines.